Call: 08045811646

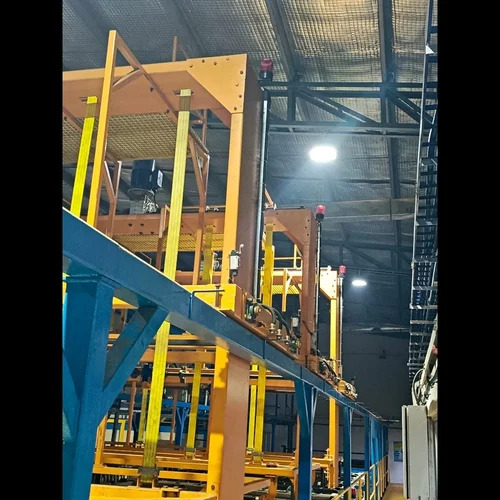

Automatic Electroplating Plant

Price 3000000 INR/ Unit

MOQ : 1 Unit

Automatic Electroplating Plant Specification

- Frequency

- 50 Hertz (HZ)

- Usage & Applications

- Industrial

- Material

- Stainless Steel

- Automatic Grade

- Automatic

- Drive Type

- Electric

- Voltage

- 440 Volt (v)

- Capacity

- 40 Kg

- Features

- Stable operation

- Surface Finish

- Coated

Automatic Electroplating Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 2-10 Days

- Main Domestic Market

- All India

About Automatic Electroplating Plant

The Automatic Electroplating Plant is designed for seamless industrial applications, ensuring stable operation and efficient results. Built with premium-grade stainless steel, this electroplating plant offers durability and long-term performance. With an automatic operational mechanism, it simplifies industrial processes and boosts productivity. Powered by an electric drive system with a robust voltage of 440 Volts, the plant operates at a frequency of 50 Hertz, delivering consistent and reliable electroplating outcomes. Its coated surface finish ensures protection against corrosion, while the 40 Kg capacity makes it suitable for handling substantial workloads. This machine is an excellent solution for industrial settings requiring precision and reliability in metal finishing processes.

FAQs of Automatic Electroplating Plant:

Q: What type of material is used in the Automatic Electroplating Plants construction?

A: The Automatic Electroplating Plant is constructed using durable stainless steel for increased longevity and reliability.Q: What is the operational capacity of the Automatic Electroplating Plant?

A: The plant boasts a capacity of 40 Kg, making it suitable for substantial industrial workloads.Q: What powers the Automatic Electroplating Plant?

A: The plant is powered by an electric drive, operating at 440 Volts and a frequency of 50 Hertz.Q: How does the surface finish of the plant contribute to its performance?

A: The coated surface finish ensures corrosion resistance, enhancing the plants durability and operational stability.Q: Is the operation of this electroplating plant manual or automatic?

A: The electroplating plant operates automatically, simplifying processes and improving efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry